Carton Cardboard High Speed Automatic Die-cutting And Creasing Machine

Carton cardboard die-cutting and creasing machine China suppiler

- Feida automatic paper feeding, with a maximum speed of 7000 pieces per hour

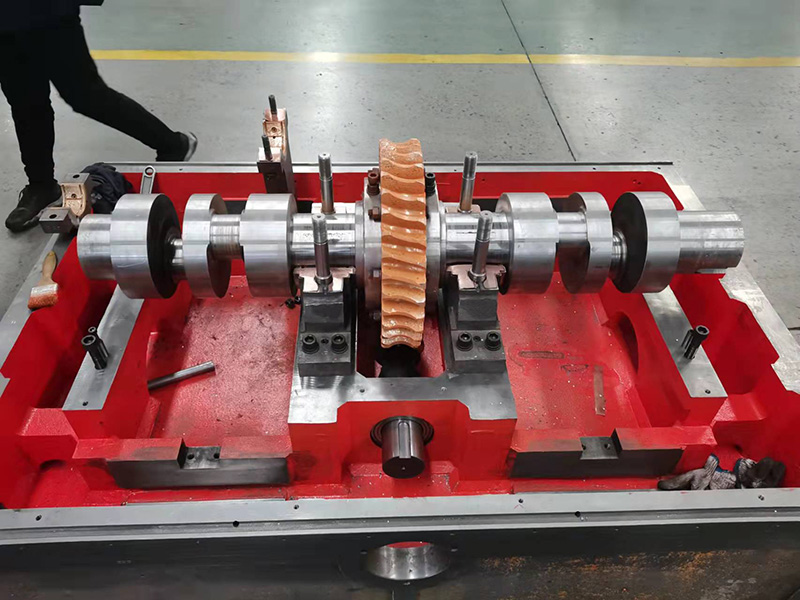

- Wallboard, gear, turbine, worm and other components are made of high material and high precision processing.

- It is convenient and fast to replace the template.

- All electrical components are international famous brands.

- Focus on die-cutting machine manufacturing experience for 20 years.

- Optional automatic waste cleaning function

Share This Page

Technical parameter

| Item | Parameters |

| Model | MY-1300 |

| Die cutting type | Pressed flat die cutting(Lower side is movable while upper side is unmovable) |

| Max paper transmitting size | 1320*980mm |

| Min paper transmitting size | 400*500mm |

| Max die cutting size | 1300*960mm |

| Min gripper size | 8mm |

| Max die cutting pressure | 350N/cm² |

| Paper processed | Cardboard 200-2000 gsm

Corrugated board ≦ 7mm |

| Max die cutting speed | 4600 sheets/h |

| Max feeding pile height | 1400mm(above the level) |

| Min feeding pile height | 1250mm(above the level) |

| Main motor power | 11 kw |

| Total power | ~18 kw |

| Total weight | ~16.5 T |

System introduction

Feeding and Collecting Part

- fThe extra feeder can do paper and corrugated board,Install the vacuum pump of BECKER.

- At the middle of head install the monitor ,worker can easily see the back

- Pre-paper pile design and special pneumatic bench can save much time

- The non-stop sampling system can check the board accurate without stop the machine

Feeding table

- Additional brush wheels and pressing wheels for thin paper and corrugated board running

- Advance push and pull lay of registration can assure the die cutting precision

- Rikko light front lay detection system prevent the slanting paper move in main body

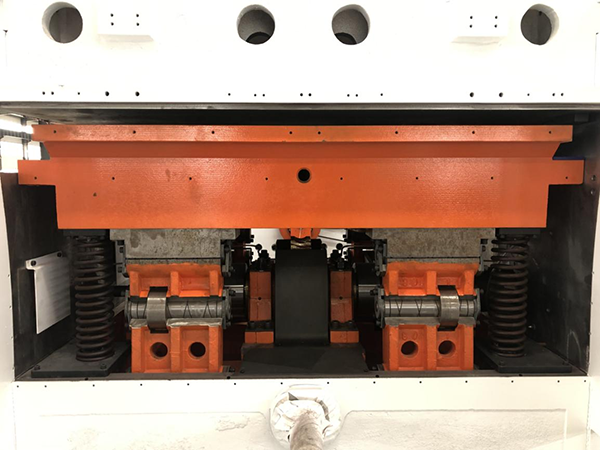

Main body

- Adopt automatic centralized lubricating system and setting main chain lubricating system by HMI

- Patented design shock absorption system can prolong the life of main body and increase the pressure

- The intermittent gearbox made in Taiwancan assure the accurate registration and decrease the gripper attack

Diecutting part and Delivery system

- Diecutting chase fixed accurately by pneumatic lock system

- Diecutting plate is putted in and out by air floating device

- Electric clutch system of main chain can assure the chain steady when it is stopped at high speed

- Main chain and assist chain is lubricated periodically controlled by PLC

- Protection window of diecutting can hold the main body clean

- Lightweight and durable aluminum alloy gripper bars with chain of Renold UK OR IWIS GERMANY ensure accurate

GET A FREE QUOTATION

Related Products